99 Ford Explorer Timing/Heads Gasket Replacement: Difference between revisions

| (11 intermediate revisions by the same user not shown) | |||

| Line 9: | Line 9: | ||

* [https://www.youtube.com/watch?v=WJax1KPtRB8&ab_channel=CloyesGear%26Products%2CInc. Cloyes Timing Tutorial (Cloyes kit# 9-0398SB)] | * [https://www.youtube.com/watch?v=WJax1KPtRB8&ab_channel=CloyesGear%26Products%2CInc. Cloyes Timing Tutorial (Cloyes kit# 9-0398SB)] | ||

* [https://www.youtube.com/watch?v=mbY0HSFJiVs Torque Head Bolts] | * [https://www.youtube.com/watch?v=mbY0HSFJiVs Torque Head Bolts] | ||

* Platinum Garage | |||

*# [https://www.youtube.com/watch?v=C_PuUmACtsk Good Rebuild Video w/ Purchasing Recommendations] | |||

*# [https://www.youtube.com/watch?v=Da7SK6uCE8Y&t=122s Very Good Engine Installation Video] | |||

* [https://www.explorerforum.com/forums/threads/sohc-v6-torque-specifications.406687/#post-3289479 Torque Specifications] | |||

== Tips for Pulling Engine == | == Tips for Pulling Engine == | ||

| Line 158: | Line 162: | ||

#* [https://www.ebay.com/itm/180856722756?_trkparms=aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D232195%26meid%3D85ccb64ff8d542bcbd589382bf0bfa59%26pid%3D101195%26rk%3D1%26rkt%3D12%26mehot%3Dag%26sd%3D160974704241%26itm%3D180856722756%26pmt%3D1%26noa%3D0%26pg%3D2047675%26algv%3DSimplAMLv9PairwiseUnbiasedWebWithSearchFilterPromotion%26brand%3DAftermarket+Products&_trksid=p2047675.c101195.m1851 Gasket kit] ($103) | #* [https://www.ebay.com/itm/180856722756?_trkparms=aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D232195%26meid%3D85ccb64ff8d542bcbd589382bf0bfa59%26pid%3D101195%26rk%3D1%26rkt%3D12%26mehot%3Dag%26sd%3D160974704241%26itm%3D180856722756%26pmt%3D1%26noa%3D0%26pg%3D2047675%26algv%3DSimplAMLv9PairwiseUnbiasedWebWithSearchFilterPromotion%26brand%3DAftermarket+Products&_trksid=p2047675.c101195.m1851 Gasket kit] ($103) | ||

# [https://www.amazon.com/dp/B00TM1CVM8/ref=au_as_r?_encoding=UTF8&Make=Ford%7C54&Model=Explorer%7C663&Year=1999%7C1999&ie=UTF8&newVehicle=1&vehicleId=1&vehicleType=automotive Oil Pump] ($70) | # [https://www.amazon.com/dp/B00TM1CVM8/ref=au_as_r?_encoding=UTF8&Make=Ford%7C54&Model=Explorer%7C663&Year=1999%7C1999&ie=UTF8&newVehicle=1&vehicleId=1&vehicleType=automotive Oil Pump] ($70) | ||

= Reinstallation = | |||

== Crankshaft Installation == | |||

# Ensure everything is as clean as possible and blow out oil galleys on block and crankshaft | |||

# Install the main bearings to block dry. Ensure oil galley markings line up | |||

# Very gently install the crankshaft | |||

# Apply small bead of high temp sealant to the rear main bearing cap | |||

# Install the main bearing caps taking note of the arrows and numbers (relative to front of engine) | |||

# Clearances should be: | |||

#* Desired 0.0008-0.0015 | |||

#* Allowable 0.0005-0.0019 | |||

# Torque bolts to '''72 ft lbs''' in the following order, 3, 2, 4, 1 | |||

# Ensure crank turns freely | |||

== Piston Installation == | |||

# Check ring clearance is no greater than '''.015''' | |||

# Lubricate piston rings and install. Ensure that gaps are correctly spaced around the circumference of the piston | |||

# Install new rod bolts | |||

# Install rod bearings | |||

# Add rubber hose to rod bolts and feed | |||

# Using piston installation tool, install piston ensuring correct piston numbering and arrow alignment | |||

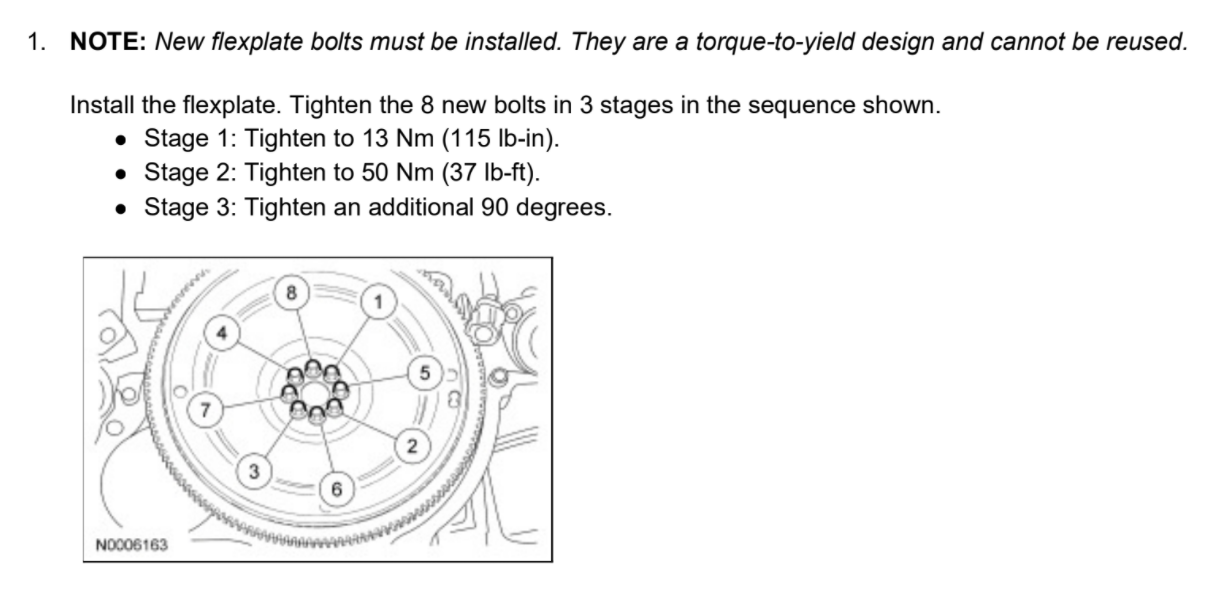

[[File:4.0 sohc flexplate torque sequence.png]] | |||

Latest revision as of 04:47, 31 July 2021

Resources

- Excellent 4 part FordTechMakuloco series + Bonus Video

- Cloyes Timing Tutorial (Cloyes kit# 9-0398SB)

- Torque Head Bolts

- Platinum Garage

- Torque Specifications

Tips for Pulling Engine

General

- Take lots of pictures

- Keep bolts with what they belong too (if possible)

Prep

- Spray Rust Pentrant

- Exhaust Manifold

- Engine Mounts

- Drain Coolant

- Drain Oil

- Mark Plug Wires

Underneath

- Disconnect Exhaust Manifold

- Mark One Bolt on Torque Converter w/ White Paint

Front

- Alternator

- Power Steering

- Compressor

- Intake (Upper and Lower)

- Fan, Radiator, Condensor

Engine Mount

- Remove Engine Mount to Frame Nuts

- Loosen Engine Mount to Engine Bolts

Initial Lift

- Connect chains to front of left head and back of right head

- Support transmissision w/ jack and block of wood

- Lift Engine Slightly

- Once engine weight is on hoist, remove engine mount entirely to make it easier to dismount/mount transmission

- Remove last 2 bellhousing bolts

- Disconnect fuel line (do it last so you don't smell fuel)

Remove

- Raise a few Inches

- Shake free from transmission

- Verify that everything is free

- Gently raise a few inches at a time verifying clearances

- Raise to clear front radiator area, drag engine free, but move very slowly to prevent a tip

- Once clear of truck, lower to reduce center of gravity

Post Removal Cleanup

- Make sure torque converter is fully seated

- Put transmission on jack stand

- Put rags in exhaust pipes

- Use equalizer to lift back of engine and finish draining coolant

- Plug intake holes with rags

Flex Plate Removal and Engine Mounting

- Remove 1 bolt

- With white paint marker, mark threads and hole

- Remove flex plate

- Remove bracket covering jack shaft

- For bottom engine mount holes, tap dowels with M12 tap, thread bolt, and then use slide hammer to pull dowels

Engine Teardown (Top)

- Blow everything off well with compressed air

- Ensure fuel line isn't leaking

- May require heating EGR bolt well to remove

- Take pictures of front of engine

- Remove Parts

- Waterpump

- Thermostat Housing

- Dampener

- Remove 19mm bolt in center

- Insert M8 1.25 thread 100mm long bolt into dampener holes

- There's nothing to press against, so insert metal rod of some kind inside hole

- Install dampener removal tool and press dampener off

- Front Cover (Waterpump Area) (leave top bolt in loose and pry part is top right)

- Valve Covers

- Roller followers (need rocker removal tool OTC 303-567)

- May not be able to do 1 end rocker so move cam neutral)

- See 22:52

- Remove tensioners (1 1/16")

- Camshaft Sprocket Bolts

- Driver side (normal right hand thread)

- Passenger side (left hand thread) !!

- Remove Camshaft caps and pull camshaft and caps together (maintain order)

- Remove last rocker roller

Engine Teardown (bottom)

- Pull lower pan (10mm)

- Remove intake tube (lift while unscrewing)

- Remove t-30 torque bolts in back of block (1 long, 1 short)

- Remove 8 inner bolts (13mm)

- Remove outside bolts and nuts (10mm)

- Gently tap front to break seal

- Remove gasket (ideally in 1 piece to reduce cleanup)

- Look for any plastic debris

Engine Teardown (timing)

- Take lots of pictures and note sprocket orientation

- Remove main tensioner

- Remove Jackshaft Bolt (E18)

- Pull Jackshaft sprocket, chain, and Crank sprocket together (keep them in the correct orientation to make assembly more obvious)

- Front cover gasket

- Cassette bolts near jackshaft (10mm) and on head (torx)

- Remove Front (Driver )Cassette

- Very annoying

- Use prybar from top to distort pin

- Then use another prybar to push cassette hinge from bottom up through head

- Remove Rear (Passenger) Cassette

- Less annoying

- Torx on block

- 10mm bolt on head

- Remove rear Jackshaft Bolt

- Remove plug by tapping on it to deform it to access Jackshaft bolt (T55)

- Put Sprocket back on Front and Hold with Rag

- Use impact to Remove rear jackshaft bolt (T55)

- Use pick to separate rear jackshaft sprocket and work chain and sprocket out of head

Needed Tools

- 5lb slide hammer ($85)

- Ford Timing Kit ($65)

- M12 bolt for Pulling Engine Dowels

- Engine Hoist Leveler ($32)

- Dampener Removal Tool ($22)

- Rocker Removal Tool (OTC 303-567) ($21)

- External Torx Set ($25)

- 3m Broloc Cleaning Discs ($32)

- Red Scotch Brite ($9)

- Permatex Engine Assembly Lube ($8)

- 100mm M10 1.25 Bolt for Engine Stand Mounting x4

Parts to Replace

- Jackshaft Bolts (TTY, but I can't seem to find anywhere)

- Timing Components

- Heads

- Remanufactured Heads @alliedautoparts ($550) (reviews are all over the place)

- Servicing of Heads @ Southern Performance in Atoka TN ($450)

- 6 DESNO Platinum Spark Plugs ($20)

- Head Gasket Kits

- Gasket kit ($103)

- Oil Pump ($70)

Reinstallation

Crankshaft Installation

- Ensure everything is as clean as possible and blow out oil galleys on block and crankshaft

- Install the main bearings to block dry. Ensure oil galley markings line up

- Very gently install the crankshaft

- Apply small bead of high temp sealant to the rear main bearing cap

- Install the main bearing caps taking note of the arrows and numbers (relative to front of engine)

- Clearances should be:

- Desired 0.0008-0.0015

- Allowable 0.0005-0.0019

- Torque bolts to 72 ft lbs in the following order, 3, 2, 4, 1

- Ensure crank turns freely

Piston Installation

- Check ring clearance is no greater than .015

- Lubricate piston rings and install. Ensure that gaps are correctly spaced around the circumference of the piston

- Install new rod bolts

- Install rod bearings

- Add rubber hose to rod bolts and feed

- Using piston installation tool, install piston ensuring correct piston numbering and arrow alignment